TTM Machinery Precision Tuag Thiab Stamping Part Sample

Video

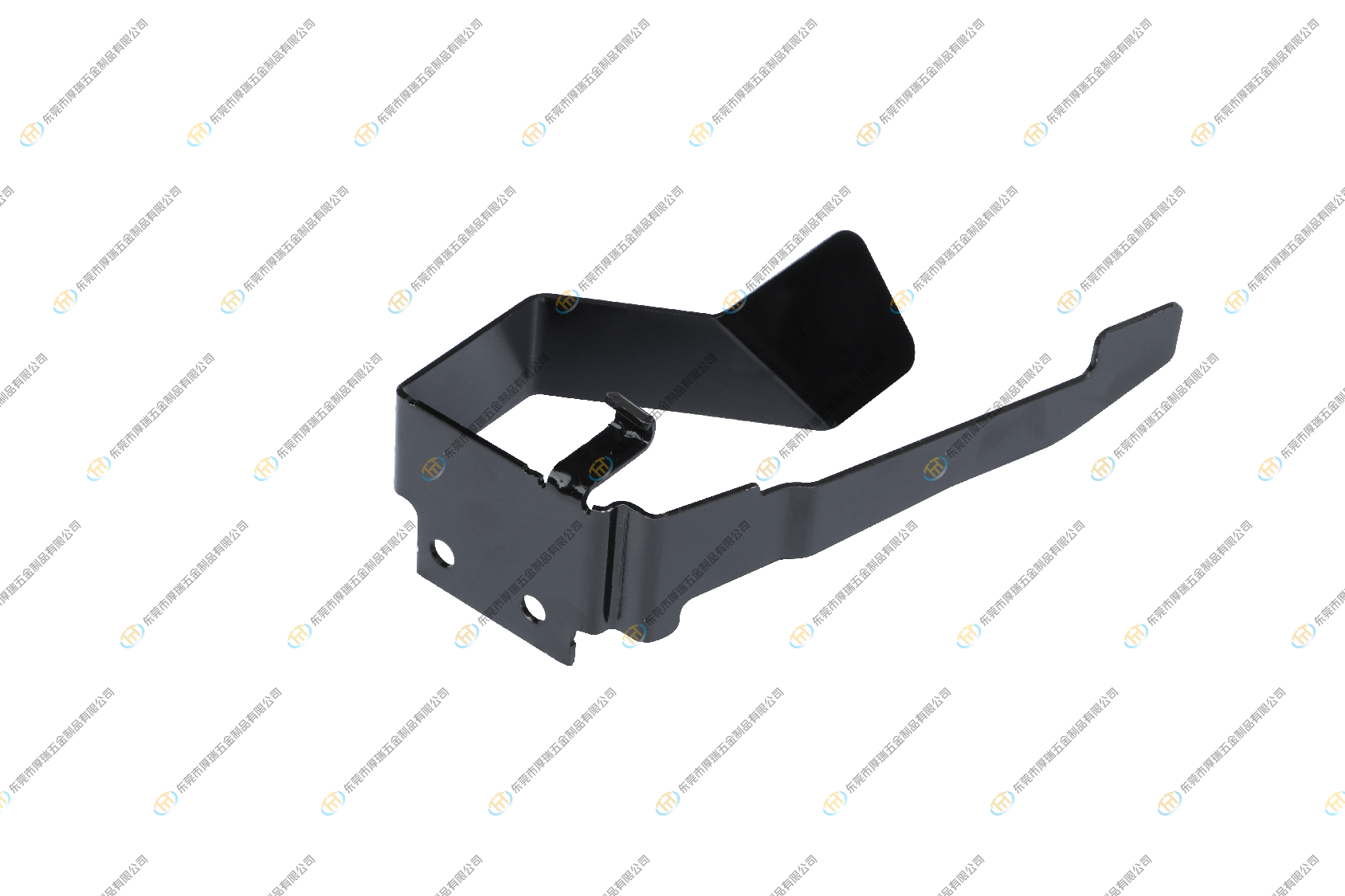

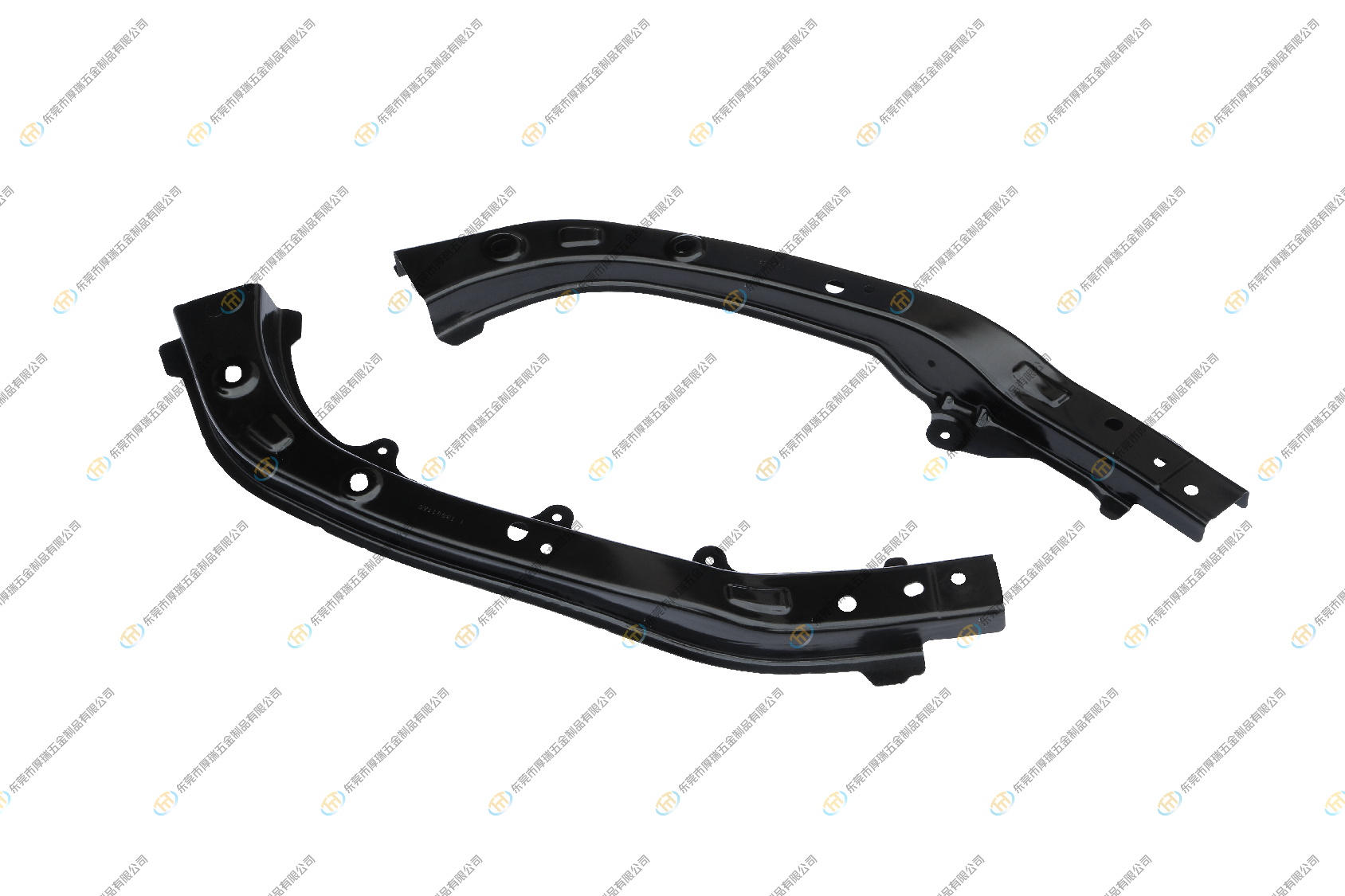

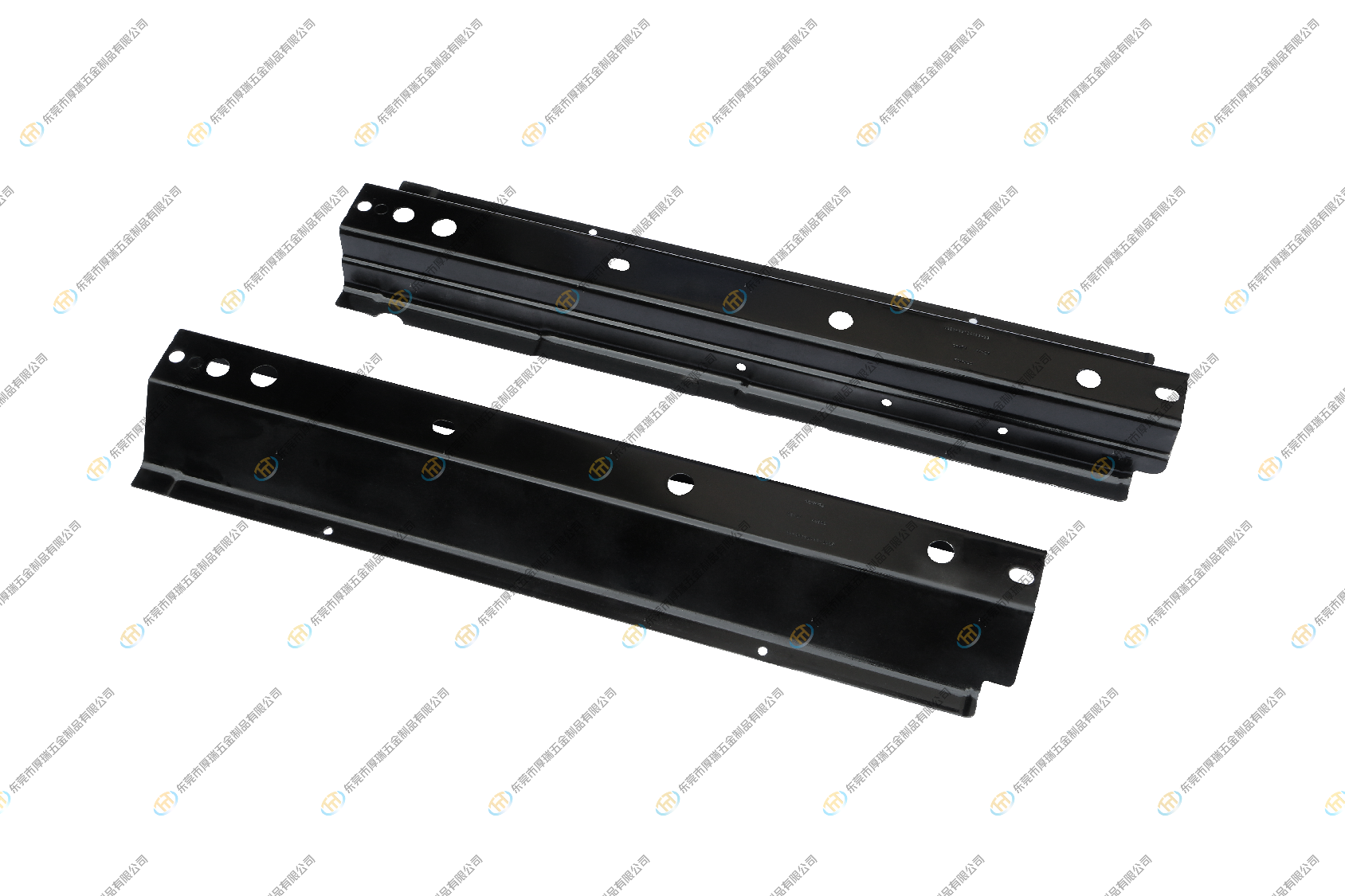

Yam khoom

- Zaum rov qab

- Roj teeb Cradle

- Lub txaj txaj

- Main channel

- lwm.

Cov duab ntau lawm

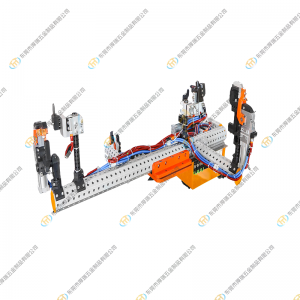

Taw qhia

Stamping qhov chaw xa mus rau qhov chaw ua los ntawm stamping hlau los ntawm cov tuag.Nws muaj qhov zoo ntawm qhov siab precision, lub teeb yuag, siab zog, thiab tus nqi qis, thiab yog dav siv hauv tsheb, hluav taws xob, tshuab thiab lwm yam.Cov qauv stamping ib feem yog qee cov qauv tsim rau lub hom phiaj ntawm kev txheeb xyuas seb tus qauv tsim puas tau raws li qhov yuav tsum tau ua, kuaj xyuas qhov zoo, thiab txhawb kev lag luam.Feem ntau, cov qauv ntawm cov khoom stamping uas tsim los ntawm TTM yuav tsum tau soj ntsuam nruj thiab kuaj kom ntseeg tau tias lawv cov kev ua tau zoo thiab ua tau raws li cov qauv thiab ua tau raws li cov neeg siv khoom xav tau.

Peb Txoj Haujlwm Ua Haujlwm

1. Tau txais daim ntawv xaj khoom------>2. Tsim------>3. Kev lees paub cov duab kos / kev daws teeb meem------>4. Npaj cov ntaub ntawv------>5. CNC------>6. CWM------>6. Kev sib dhos------>7. CMM-> 8. Kev tshuaj xyuas------>9. (kev tshuaj xyuas thib 3 yog xav tau)------>10. (Internal / cov neeg siv khoom ntawm qhov chaw)------>11. Ntim (ntoo lub thawv)------>12. Kev xa khoom

Manufacturing kam rau ua

1. Lub Flatness ntawm Base Phaj 0.05/1000

2. Lub Thickness ntawm Base Phaj ± 0.05mm

3. Qhov Chaw Datum ± 0.02mm

4. Qhov Nto ± 0.1mm

5. Kev Ntsuas Pins thiab Qhov Qhov ± 0.05mm

.png)

.png)