Precision Stamping Tuag Rau Tsheb Rooj Qhov Hlau Stamping Tuag Pwm Manufacturers

Video

Khoom Paub meej

Taw qhia ntxaws

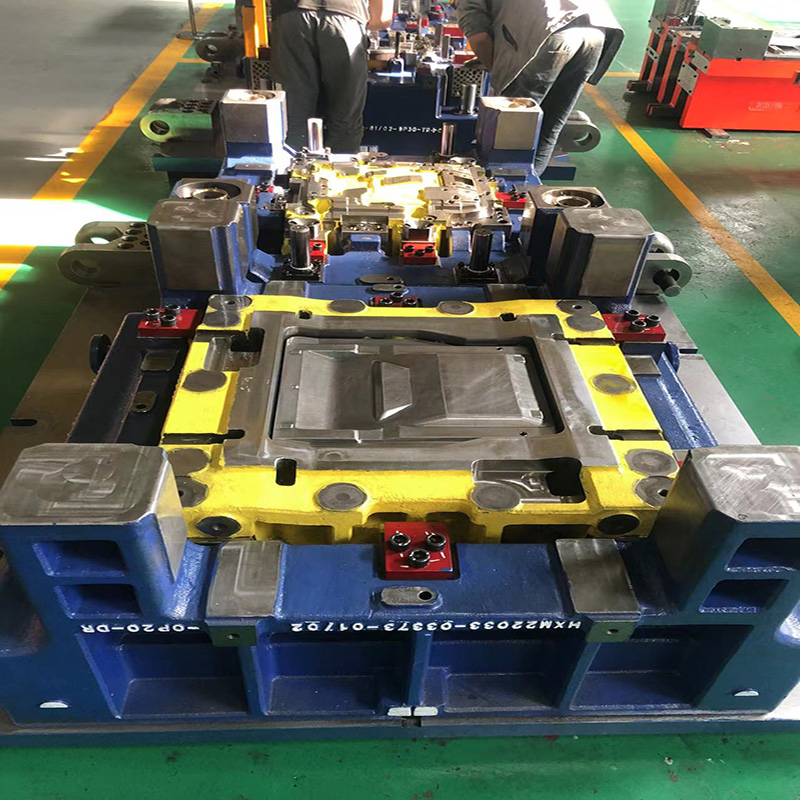

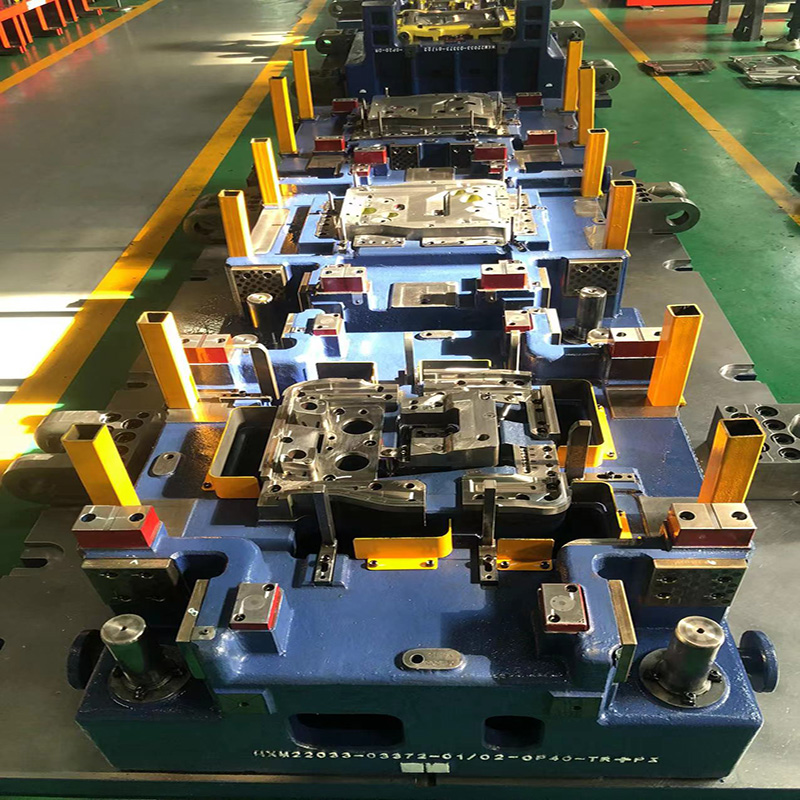

Lub rooj zaum hauv lub tsheb Cov khoom siv kho vajtse muaj cov kev xav tau siab rau ntu ci ntsa iab, qhov chaw qhov tseeb, tig qhov siab thiab qhov chaw sab nraud.Ntawm lawv, stamping tshuab yog lub tshuab tseem ceeb hauv kev tsim cov khoom siv tsheb.Kev tsim ntawm TTM lub rooj zaum hauv tsheb pwm pwm stamping tuag tuaj yeem txo cov nqi ntawm cov khoom thiab txhim kho cov khoom zoo, ua kom lub sijhawm siv sijhawm luv, thiab lwm yam.

Txoj Haujlwm Ua Haujlwm

1. Tau txais daim ntawv xaj khoom------>2. Tsim------>3. Kev lees paub cov duab kos / kev daws teeb meem------>4. Npaj cov ntaub ntawv------>5. CNC------>6. CWM------>6. Kev sib dhos------>7. CMM-> 8. Kev tshuaj xyuas------>9. (kev tshuaj xyuas thib 3 yog xav tau)------>10. (Internal / cov neeg siv khoom ntawm qhov chaw)------>11. Ntim (ntoo lub thawv)------>12. Kev xa khoom

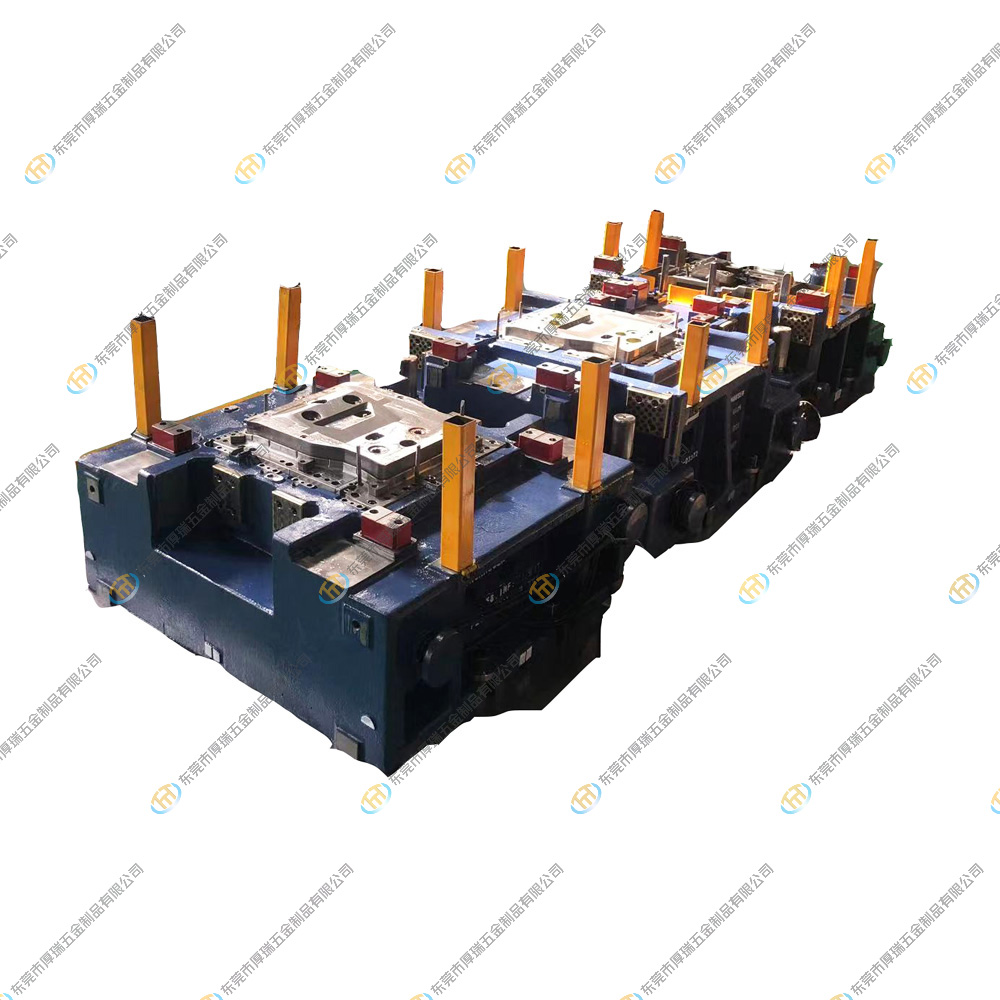

Manufacturing kam rau ua

1. Lub Flatness ntawm Base Phaj 0.05/1000

2. Lub Thickness ntawm Base Phaj ± 0.05mm

3. Qhov Chaw Datum ± 0.02mm

4. Qhov Nto ± 0.1mm

5. Kev Ntsuas Pins thiab Qhov Qhov ± 0.05mm

.png)

.png)