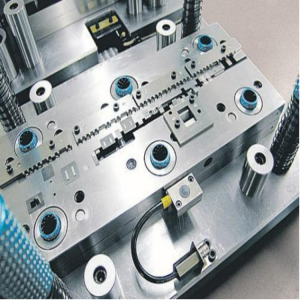

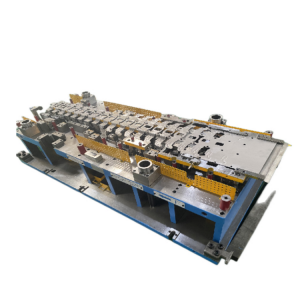

TTM Group tau tsim nyob rau hauv 2017 raws li kev tsim cov hlau stamping tuag, fixture & jigs, automation khoom rau kev lag luam automotive.In TTM, peb muaj kev nplua nuj nyob rau hauv steel & casting progressive cuab tam, hloov thiab ib lub cuab tam, cov khoom yog dav siv nyob rau hauv automotive qauv, rooj zaum , hauv qab-lub cev, chassis thiab lwm yam.Thiab peb xav qhia tias "Yuav ua li cas txo tus nqi ntawm lub tsheb stamping tuag?"

Qhov tsab xov xwm no feem ntau tsom xam lub tswv yim ntawm kev txo tus nqi ntawm lub tsheb stamping tuag, thiaj li muab kev qhia rau cov lag luam xav tau, thiab pab cov tuam txhab ua tiav cov nqi tswj kev ua haujlwm ntawm tsheb.

Ua ke nrog kev lag luam, thev naus laus zis thiab lwm yam, kev txo nqi ntawm lub tsheb stamping tuag feem ntau muab faib ua cov tswv yim hauv qab no

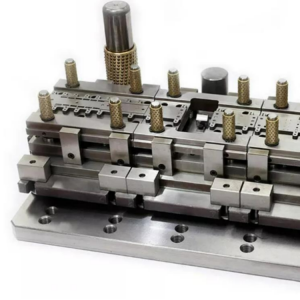

1. Faib cov khoom qib ntawm cov pwm

Yog tias kev lag luam tsheb xav kom txo qis tus nqi ntawm cov nyiaj stamping tuag, nws yuav tsum tshem tawm cov khoom pov tseg hauv kev tsim khoom.Kev lag luam tsheb tuaj yeem faib cov stamping tuag raws li qhov zoo ntawm cov ntaub ntawv ntawm stamping tuag thiab muab faib ua qib, yog li kev lag luam tsheb tuaj yeem xaiv cov qib sib txawv ntawm stamping tuag raws li qhov xav tau ntawm kev tsim tsheb, uas tsis tuaj yeem txhim kho. kev ua haujlwm ntawm kev tsim tsheb, tab sis kuj ua rau lub tsheb ua tau raws li kev xav tau ntau dua.Nyob rau hauv cov txheej txheem ntau lawm, yog tias kev lag luam tsheb xav tswj cov khoom ntau, nws tuaj yeem hloov cov qib kev xaiv ntawm stamping tuag, uas tuaj yeem zam kev lag luam loj.

2. lav qhov kev ua haujlwm ntawm kev ua haujlwm

Nyob rau hauv cov txheej txheem ntawm kev tsim tsheb, cov kev cai rau kev siv cov stamping tuag yog qhov siab.Tsis tsuas yog cov neeg ua haujlwm yuav tsum xaiv cov cuab yeej ua haujlwm tus qauv, tab sis lawv kuj yuav tsum tau ua kom paub siv cov stamping tuag kom tsis txhob pov tseg ntawm stamping tuag hauv cov txheej txheem tsim khoom.Vim tias lub rooj cob qhia ntau lawm yuav tsum tsim kom muaj ntau lub tshuab stamping tuag, uas yuav ua rau tus nqi ntawm cov tsheb ntau lawm, kev lag luam tsheb yuav tsum ua kom tiav cov khoom tuag raws li qhov xav tau tiag tiag rau tsheb tuag.Nyob rau tib lub sijhawm, kev lag luam automotive tuaj yeem ua cov khoom siv stamping tuag los txhim kho kev siv cov khoom siv thiab txhawb kev txhim kho kev lag luam tsheb.Yog li ntawd, kev lag luam tsheb yuav tsum tau ua kom ntseeg tau cov qauv kev ua haujlwm ntawm cov neeg ua haujlwm kom ntxiv dag zog rau kev tswj tus nqi ntawm kev lag luam tsheb.

3. Optimization ntawm tiav stamping tuag

Txhawm rau txhim kho kev siv tus nqi ntawm stamping tuag nyob rau hauv cov txheej txheem tsim tsheb, kev lag luam tsheb tuaj yeem ua kom tsim nyog rau kev txhim kho cov stamping tuag, uas tuaj yeem txo cov khoom pov tseg hauv cov txheej txheem ntau lawm.Txhawm rau txo cov khoom pov tseg ntawm cov khoom siv, kev lag luam tsheb tuaj yeem kho cov qauv ntawm cov stamping tuag.Piv txwv li, nce qhov chaw sib cuag ntawm lub stamping tuag thiab cov khoom tuaj yeem ua tiav los ntawm kev txhim kho ob lub qhov rooj, uas tuaj yeem tsis tsuas yog cuam tshuam lub ntiajteb txawj nqus ntawm lub stamping tuag tab sis kuj txhim kho lub siab stamping.Kev siv cov pwm tuaj yeem txhim kho kev tsim khoom ntawm lub tsheb.Kev lag luam automotive tuaj yeem ua tiav qhov kev ua kom zoo ntawm cov stamping tuag raws li qhov xav tau tiag tiag, kom ua tiav cov txiaj ntsig zoo tshaj plaws.

Saum toj no yog txhua yam peb xav qhia hauv kab lus no, vam tias yuav pab tau koj txhua tus!

Post lub sij hawm: Apr-04-2023

.png)

.png)