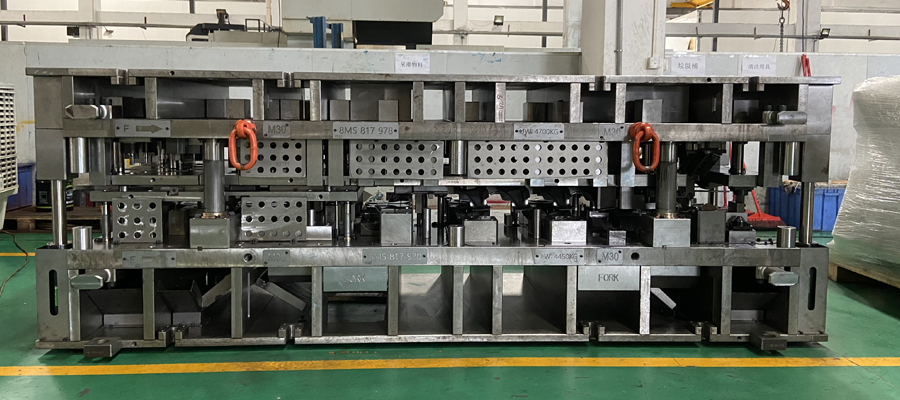

Progressive tuagyog ib qho cuab yeej tshwj xeeb uas siv rau hauv cov hlau stamping kev ua haujlwm los tsim cov khoom sib txawv thiab meej.Nws muaj cov chaw nres tsheb lossis theem uas cov hlau hla dhau, nrog rau txhua qhov chaw nres tsheb ua haujlwm tshwj xeeb ntawm cov khoom siv.Qhov no tso cai rau kev txhim kho shaping thiab tsim ntawm ib feem, uas ua rau muaj kev nce qib thiab raug piv rau cov txheej txheem stamping ib txwm.

Ib qho ntawm cov yam ntxwv tseem ceeb ntawm ance tuagyog nws lub peev xwm los ua ntau yam haujlwm ib txhij.Raws li cov hlau sawb hla txhua qhov chaw nres tsheb, cov cuab yeej sib txawv thiab cov tuag tau siv los ua cov haujlwm tshwj xeeb xws li txiav, khoov, shaping, thiab sib sau.Qhov no tsis tsuas yog txuag lub sijhawm tab sis kuj ua kom cov txiaj ntsig zoo ib yam thiab zoo ib yam thoob plaws hauv cov txheej txheem tsim khoom.

Ib qho tseem ceeb feature ntawm ib tug zuj zus tuag yog nws versatility.Nws tuaj yeem siv los tsim ntau yam ntawm qhov chaw, los ntawm cov khoom tiaj tus yooj yim mus rau cov duab zoo sib xws.Los ntawm kev sib xyaw cov cuab yeej sib txawv thiab tuag ntawm txhua qhov chaw nres tsheb, qhov tuag tuaj yeem ua kom haum rau ntau yam kev tsim thiab kev ua haujlwm thib ob, tso cai rau kev tsim khoom ntawm cov khoom siv tshwj xeeb nrog cov yam ntxwv sib txawv thiab cov lus qhia tshwj xeeb.

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev siv cov tuag tuag yog nws cov kev ua haujlwm siab thiab tsim khoom.Lub nruam txav ntawm cov hlau sawb los ntawm kev tuag minimizes downtime thiab tso cai rau cov khoom sai sai ntawm qhov chaw.Tsis tas li ntawd, cov txheej txheem automated ntawm cov txheej txheem tshem tawm qhov xav tau ntawm kev siv phau ntawv, txo cov nqi zog thiab ua kom tag nrho cov khoom tsim tawm.

Cov tuag tuag kuj muaj kev txhim kho qhov tseeb thiab qhov tseeb hauv ib feem ntau lawm.Cov cuab yeej ua tib zoo tsim thiab machined los xyuas kom meej nruj tolerances thiab kaw qhov ntev tswj.Qhov no yog qhov tseem ceeb tshwj xeeb hauv kev lag luam xws li automotive thiab aerospace, qhov chaw yuav tsum tau ua kom tau raws li cov qauv zoo thiab haum ua ke seamlessly.

Tsis tas li ntawd, cov tuag ua tiav yog tsim los rau kev ua haujlwm ntev thiab ntev.Cov ntaub ntawv siv, xws li cov hlau tawv tawv, tiv taus hnav thiab txo qhov kev xav tau ntawm cov cuab yeej nquag hloov lossis kho.Qhov no ua rau cov nqi txuag thiab nce sijhawm ntau lawm, vim tias qhov tuag tuaj yeem ua tau zoo nyob rau lub sijhawm ntev.

Hais txog kev teeb tsa thiab kev hloov pauv, kev tuag zuj zus tuaj yeem siv sijhawm ntau dua piv rau lwm txoj hauv kev stamping.Txawm li cas los xij, thaum qhov tuag tau teeb tsa kom raug, nws tuaj yeem tsim cov khoom ntim siab tsis tu ncua thiab nrog kev cuam tshuam tsawg kawg nkaus.

Txhawm rau kom ua tiav, cov yam ntxwv tseem ceeb ntawm kev nce qib tuag suav nrog nws lub peev xwm los ua ntau yam haujlwm ib txhij, nws muaj peev xwm tsim tau ntau yam, nws ua haujlwm siab thiab tsim khoom, nws qhov tseeb thiab qhov tseeb, thiab nws cov kav ntev thiab ntev.Cov yam ntxwv no ua rau kev tuag zoo ib yam khoom muaj txiaj ntsig hauv kev ua haujlwm hlau stamping, ua rau cov tuam txhab tsim cov khoom sib txawv thiab meej ntawm tus nqi nrawm dua thiab txhim kho qhov sib xws.

Post lub sij hawm: Nov-16-2023

.png)

.png)