Nrog rau txoj kev loj hlob sai ntawm kev lag luam tsheb, cov neeg muaj kev xav tau ntau dua thiab siab dua rau kev ua tau zoo, kev ntseeg tau thiab kev zoo nkauj ntawm lub tsheb panels.Kev kos duab I-shaped yog cov txheej txheem tseem ceeb tshaj plaws hauv kev tsim cov txheej txheem ntawm lub cev.Txawm hais tias nws tsim nyog yuav txiav txim siab nws ncaj qha cuam tshuam rau qhov zoo ntawm lub tsheb panels thiab lub voj voog ntawm cov qauv tshiab.Yog li ntawd,TTMtxheeb xyuas cov txheej txheem kev kos duab ntawm lub tsheb panels, uas yog qhov zoo rau luv luvpwmtsim lub sij hawm, txhim kho cov tsos zoo ntawm panels, thiab yog li txhim kho cov kev sib tw ntawm cov lag luam.Daim ntawv no tsuas yog qhia txog cov txheej txheem kos duab ntawm sab phab ntsa sab nrauv vaj huam sib luag.

1.1 Cov khoom siv feem ntau siv rau sab panels

Kev tsim cov txheej txheem ntawm lub vaj huam sib luag sab nrauv ntawm phab ntsa sab nrauv feem ntau yog 4-5 cov kauj ruam (tsis suav nrog blanking).Txhawm rau kom ntseeg tau qhov zoo ntawm cov khoom noodle thiab txo qhov nyuaj ntawm kev debugging, feem ntau ntawm cov phab ntsa sab nrauv tam sim no ua tiav hauv tsib kauj ruam.Vim yog cov duab ntawm sab phab ntsa thiab qhov sib sib zog nqus qhov tob, cov ntaub ntawv siv feem ntau yog DC56D + Z lossis DCO7E + Z + pre-phosphating nrog cov khoom siv zoo dua qub, thiab cov khoom tuab feem ntau yog 0.65mm, 0.7mm, thiab 0.8mm ib.Xav txog kev tiv thaiv xeb thiab rigidity thiab formability ntawm cov khoom, cov khoom nyiam yog DCDC56D + Z / 0.7t.Nyob rau tib lub sijhawm, ciam teb tawg ntawm sab qhov rooj qhib muaj kev sib raug zoo nrog R lub kaum sab xis ntawm cov khoom siv tsis zoo.Qhov me me R lub kaum sab xis ntawm cov khoom tsis zoo ntawm lub qhov rooj qhib, qhov yooj yim ntawm ciam teb yog tawg.

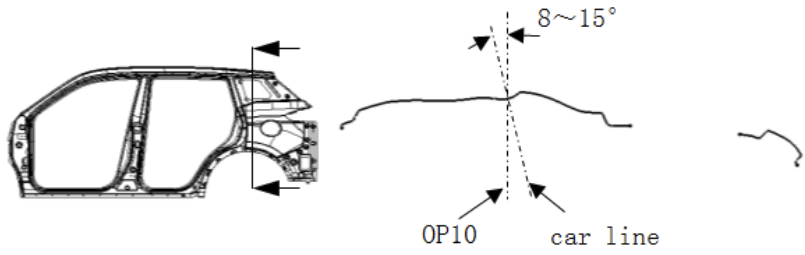

1.2 Stamping kev taw qhia ntawm sab phab ntsa sab nrauv vaj huam sib luag

Ua tib zoo xav txog cov txheej txheem kev kos duab ntawm sab phab ntsa vaj huam sib luag, feem ntau cov kev taw qhia stamping ntawm sab phab ntsa sab nrauv yog ntawm lub kaum sab xis ntawm 8-15 ° nrog Y kev taw qhia ntawm lub cev lub tsheb.

1.3 Cov ntsiab lus ntxiv rau kev mloog nyob rau sab phab ntsa sab nrauv txheej txheem

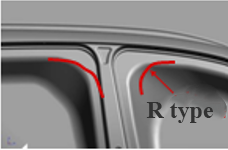

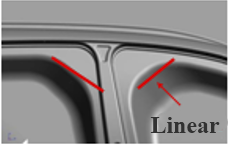

1.3.1 Cov ntsiab lus tshwj xeeb rau kev teeb tsa cov duab ntxiv ntawm sab sauv ntawm tus ncej B

Muaj ob txoj hauv kev rau kev kos cov nqaij seem ntawm lub ces kaum sab sauv ntawm tus ncej B.Ib qho yog kos cov kab sib cais ntawm lub punch ntawm kaum ntawm lub punch ze rau cov khoom zoo, uas yog, hom R.Cov duab ntawm cov nqaij seem no tuaj yeem txo txoj hauj lwm ntawm lub ces kaum sab sauv.Lub thickness thiab thinning tus nqi ntawm cov khoom tuaj yeem hloov kho kom tsis txhob tawg.Lwm qhov yog los teeb tsa txoj kab sib cais ntawm cov punch ntawm lub ces kaum ntawm daim duab punch rau ib txoj kab ncaj nraim, uas yog, txoj kab ncaj nraim.Cov duab ntawm cov nqaij seem no tuaj yeem txhim kho lub formability ntawm lub ces kaum sab sauv thiab nres Qhov saum npoo ntawm sab sauv ntawm B-pillar yog deformed.

1.3.2 Cov ntsiab lus rau kev saib xyuas hauv kev teeb tsa cov duab ntxiv ntawm cov txheej txheem ntawm txoj haujlwm ntawm lub qhov rooj qhib

Txoj kab sib cais ntawm lub qhov rooj qhib yuav tsum hloov pauv ntau li ntau tau, thiab kev hloov pauv yuav tsum tsis txhob ntse lossis tig.

1.4 Kev teeb tsa ntawm drawbeads ntawm sab phab ntsa sab nrauv panels

Vim yog cov duab ntawm sab phab ntsa, txhawm rau kom tswj tau qhov ntws ntawm cov ntaub ntawv hauv txhua qhov, ob chav tav feem ntau yog siv.Txhawm rau tiv thaiv cov drawbead los ntawm nkag mus rau hauv cov khoom nto thiab cuam tshuam rau qhov zoo ntawm cov khoom, qhov kev ncua deb ntawm drawbead thiab cov khoom nyob ze ntawm qhov pib yuav tsum tau nthuav dav, thiab tom qab ntawd txoj hauj lwm ntawm drawbead yuav tsum tau kho los ntawm CAE simulation tsom xam. siv Autoform software.Lub drawbead nyob rau hauv lub qhov rooj qhib yuav tsum du npaum li sai tau, thiab R lub kaum sab xis yuav tsum loj npaum li sai tau.

Post lub sij hawm: May-24-2023

.png)

.png)