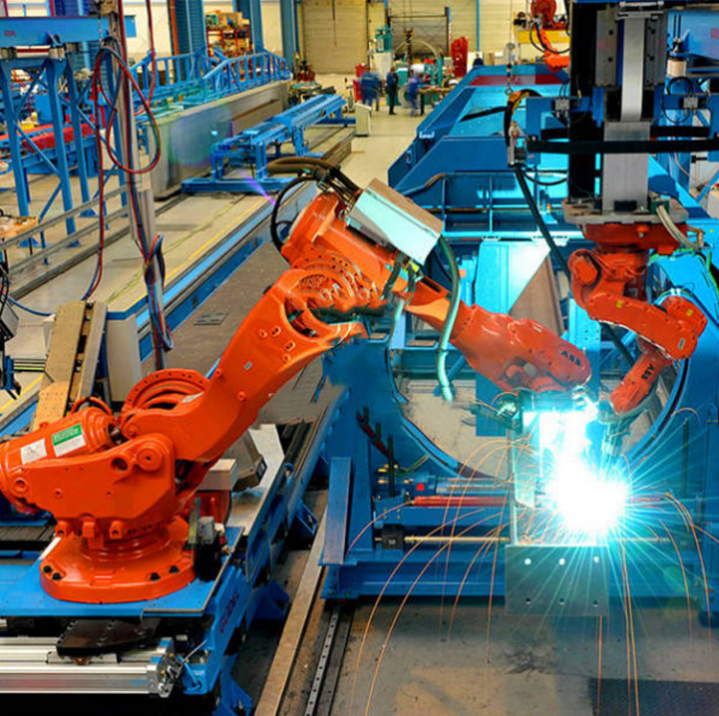

Raws li kev lag luam automotive txuas ntxiv mus, yog li automotive vuam tshuab.Ib txwm siv phau ntawv vuam tsis tuaj yeem ua tau raws li cov kev xav tau ntau lawm, thiab kev siv vuam tshuab tau dhau los ua ib feem tseem ceeb ntawm kev tsim tsheb.Tsis siv neeg vuam fixture yog ib qho ntawm cov cuab yeej tseem ceeb kom paub tsis siv neeg vuam.

Automotive tsis siv neeg vuam fixture yog hais txog cov cuab yeej siv los clamp lub workpiece thiab txoj hauj lwm, kev txhawb nqa thiab ua kom lub workpiece nyob rau hauv txoj hauj lwm yuav tsum tau vuam.Qhov no fixture yuav tsum muaj cov yam ntxwv ntawm high precision, siab rigidity, siab kev ntseeg tau thiab lub neej ntev.Nyob rau tib lub sijhawm, cov tswv yim zoo xws li kev tsim khoom thiab cov nqi zog yuav tsum tau txiav txim siab.Yog li ntawd, nws yog ib qho tseem ceeb heev los tsim thiab tsim cov khoom siv hluav taws xob zoo automation vuam fixtures.

Kev tsim thiab tsim khoom ntawm automotive automation vuam fixtures muaj xws li cov hauv qab no:

1. Kev soj ntsuam xav tau: Raws li qhov xav tau tiag tiag, txiav txim siab qhov tsis xws li hom, qhov loj, thiab cov duab ntawm lub vuam workpiece, nrog rau qhov yuav tsum tau ua rau qhov tseeb, ruaj khov, thiab kev pabcuam lub neej ntawm cov khoom siv.

2. Kev tsim qauv: Raws li tus yam ntxwv ntawm lub workpiece, tsim cov qauv qauv, txoj kev clamping, txoj kev muab tso rau, txoj kev txhawb nqa, thiab lwm yam ntawm lub fixture, thiab tib lub sij hawm, cov yam ntxwv xws li qhov nruj thiab qhov hnyav ntawm qhov xav tau fixture. xav txog.

3. Mechanical tsom xam: Los ntawm finite element tsom xam thiab lwm yam txhais tau tias, ua raws li mechanical tsom xam ntawm lub fixture, txiav txim siab nruj thiab deformation ntawm fixture, thiab optimize cov qauv ntawm lub hauv paus no.

4. Kev tsim khoom thiab kev sib dhos: Xaiv cov khoom tsim nyog thiab cov txheej txheem los tsim thiab sib sau ua ke, thiab ua qhov tseeb debugging thiab sim welding kom ntseeg tau tias qhov zoo thiab ruaj khov ntawm lub fixture.

5. Kev debugging thiab txij nkawm: Hauv kev tsim khoom, siv cov khoom siv hauv kev xyaum, xyuas cov xwm txheej ntawm cov khoom siv kho mob txhua lub sijhawm thiab ua haujlwm kho thiab kho kom ntseeg tau tias cov khoom siv tau zoo ib txwm ua haujlwm.

Nyob rau hauv luv luv, kev tsim thiab tsim khoom ntawm automotive automation vuam fixtures yog ib feem tseem ceeb ntawm cov txheej txheem automotive manufacturing.Los ntawm kev tshawb fawb thiab tsim nyog tsim thiab tsim khoom, kev tsim cov khoom lag luam thiab cov khoom lag luam zoo tuaj yeem txhim kho, cov nqi thiab kev siv tib neeg cov peev txheej tuaj yeem txo qis, thiab cov txiaj ntsig zoo tuaj yeem ua rau kev tsim kho tsheb tsim.

Post lub sij hawm: Apr-21-2023

.png)

.png)