Hauv kev tsim khoom lag luam, txhawm rau kom ntseeg tau qhov tseeb ntawm vuam, peb feem ntau yuav tsum tau sivvuam fixtures.Ib yam li ntawd, kev tsim tsheb kuj yuav tsum tau sivtsheb vuam fixtureslos tiv thaiv vuam deformation.Yog li dab tsi yog qhov ua haujlwm ntawm lub tsheb vuam fixture?

1. Kev ua haujlwm hnyav ntawm kev tso chaw, clamping thiab workpiece tig thaum manually assembling qhov chaw yog hloov los ntawm cov cuab yeej siv tshuab, uas txhim kho kev ua haujlwm ntawm cov neeg ua haujlwm.

2. Qhov tseeb thiab txhim khu kev qha thiab clamping tuaj yeem txo lossis txawm tias tshem tawm cov blanking thiab marking ua haujlwm.Qhov sib txawv ntawm qhov sib txawv ntawm cov khoom raug txo, thiab qhov raug thiab hloov pauv ntawm cov khoom raug txhim kho.

3. Khaws lub workpiece nyob rau hauv qhov zoo tshaj plaws vuam txoj hauj lwm, lub formability ntawm weld seam yog zoo, cov txheej txheem tsis xws luag yog obviously txo, thiab vuam ceev yog zoo dua.

4. Nws tuaj yeem coj kev lag luam ntau dua rau lub tuam txhab, thiab tus nqi \ sijhawm ntawm cov cuab yeej tshwj xeeb tau nqis peev hauv txhua qhov khoom hloov pauv yuav luag tsis siv.Cov cuab yeej siv tau yooj yim thiab muaj kev nyab xeeb rau kev siv, thiab cov neeg siv tuaj yeem sib cais tawm cov cuab yeej sib txawv raws li lawv xav tau.

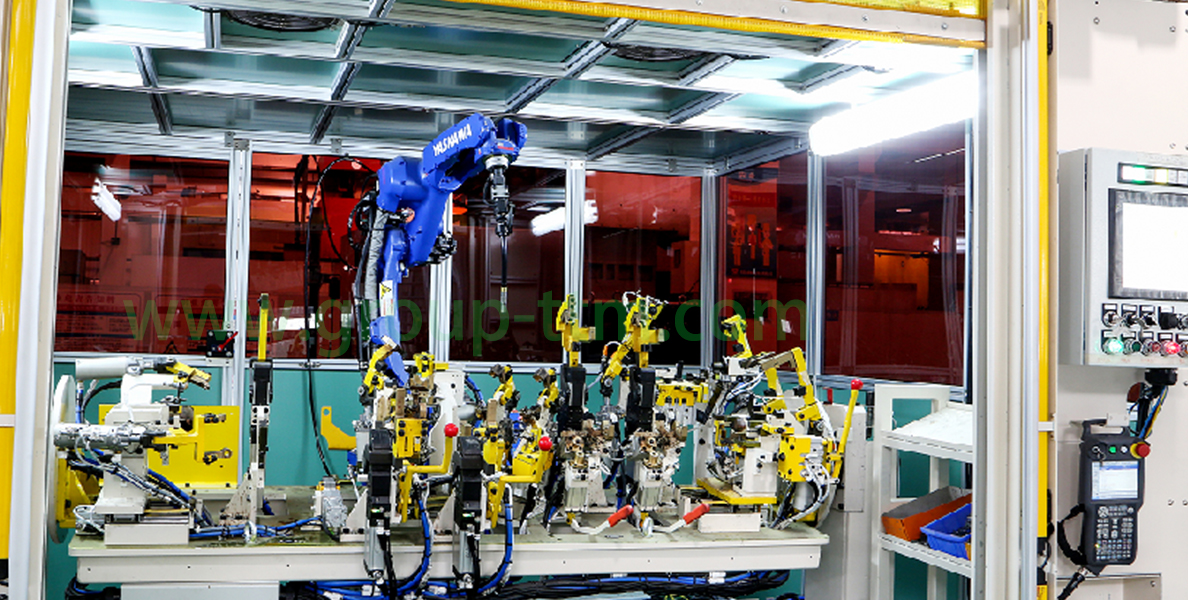

5. Lub tsheb vuam fixtures tuaj yeem nthuav dav ntawm kev siv cov txheej txheem thev naus laus zis thiab txhawb kev txhim kho kev lag luam thiab automation ntawm welded qauv ntau lawm.

6. Kev ua tau zoo yog ruaj khov heev.Yog tias cov khoom raug puas vim yog siv tsis raug, tsis tas yuav khawb tag nrho lub rooj, thiab ib feem tuaj yeem hloov tau nrog tus nqi tsawg heev.

7. Lub tsheb vuam fixtures tuaj yeem tiv thaiv thiab txo qhov vuam deformation.

Yog li ntawd, tsheb vuam fixtures ua lub luag haujlwm tseem ceeb hauv kev tsim thiab tsim cov tsheb.

Post lub sij hawm: Jun-23-2023

.png)

.png)