TTMyog ib lub tuam txhab tsim khoom lag luam uas muaj feem xyuam nrog kev tsim khoom zoo uas tau ua tiav qib siab ntawm automation.Peb tshwj xeeb hauv kev tsim tshebtshuaj ntsuam fixtures, vuam fixtures, thiabpwm.Hauv tsab xov xwm no, peb xav qhia txog qhov cuam tshuam ntawm lub zog zoo hauv kev tsim tsheb.

Cov thev naus laus zis thiab qib automation ntawm lub tsheb tsim kev lag luam tau nce siab dua thiab ntau dua, thiab ntau qhov kev cuam tshuam thiab cov khoom siv tsis yog siv hauv nws cov txheej txheem tseem ceeb, xws li hluav taws xob vuam tshuab thiab laser vuam tshuab hauv lub khw muag khoom, stamping tshuab hauv lub khw stamping, thiab zaus hloov khoom siv hauv lub khw pleev xim., tsis siv neeg ntau lawm kab nyob rau hauv lub rooj sib dhos rhiav, thiab lwm yam., cov loads muaj ib tug ntau yam feature, uas yog, lub load fluctuation yog loj heev thiab lub harmonic tiam yog loj heev.Nyob rau tib lub sijhawm, nrog cov kev xav tau txuas ntxiv ntawm lub teb chaws kom txo kev siv thiab txuag hluav taws xob, ntau lub teeb txuag hluav taws xob tau siv;tsoos motors yog maj hloov los ntawm zaus hloov dua siab tshiab drives.Cov tshiab tsis-linear loads exacerbate lub deterioration ntawm lub hwj chim zoo nyob rau hauv lub automotive manufacturing kev lag luam.

Cov teeb meem hluav taws xob tam sim no

Los ntawm kev txheeb xyuas cov kev ntsuas hluav taws xob zoo, nws pom tias cov teeb meem tseem ceeb ntawm lub zog zoo hauv kev lag luam tsheb tsim khoom yog kev sib haum xeeb, kev hloov pauv hluav taws xob thiab cov teeb meem hluav taws xob reactive, uas feem ntau muaj nyob rau hauv ntau qhov sib txuas xws li stamping, vuam, painting, powertrain thiab zaum kawg. kev sib dhos.

1. Stamping Rhiav – harmonics, voltage fluctuations thiab flicker

Lub rhiab heev loads nyob rau hauv lub rhiav stamping feem ntau yog tsom rau ntawm cov xovxwm, nrog rau cov neeg hlau thiab DC fais fab mov.Ntau lub xovxwm yog tsav los ntawm DC ceev-kho lub cev muaj zog thiab yuav tsum muaj lub zog DC ruaj khov.Robot motors yog tswj los ntawm PLC thiab tsav los ntawm zaus converters.PLC tswj circuits thiab zaus converters yog ob qho tib si yog ib tug raug rhiab load.

2.Xim khw - harmonic

Cov xim ntawm lub tsheb yog muab faib ua plaub txheej, primer, intermediate coat, basecoat thiab kua roj vanish.Tsuas yog tias cov primer yuav tsum tau txuas nrog lub roj teeb lub pas dej, lwm cov txheej txheem yog qhov zoo sib xws.Lub rhiav tsis siv neeg txau yog ib lub rhiav kev tsim khoom nrog cov txheej txheem siab heev.Kev ua tsis tiav ntawm cov khoom siv ib leeg Nws yuav cuam tshuam rau tag nrho cov txheej txheem tshuaj tsuag.

3.Tsheb ciav hlau

Lub tshuab hluav taws xob feem ntau yog hais txog lub tshuab tsim khoom, thiab qhov cuam tshuam ntawm lub zog hluav taws xob yog tsom rau ntawm CNC tshuab cov cuab yeej hauv kev cob qhia machining, nrog rau cov khoom siv thauj khoom, cov kab sib dhos, thiab kev sim platforms.Cov khoom siv kim heev thiab nyuaj downtime yuav tsum tau rov pib dua lub tshuab tsis, scrapping workpieces, cov cuab yeej puas, nres cov kab ntau lawm, tos ua haujlwm, thiab lwm yam.

4.Kev sib dhos zaum kawg - Harmonics

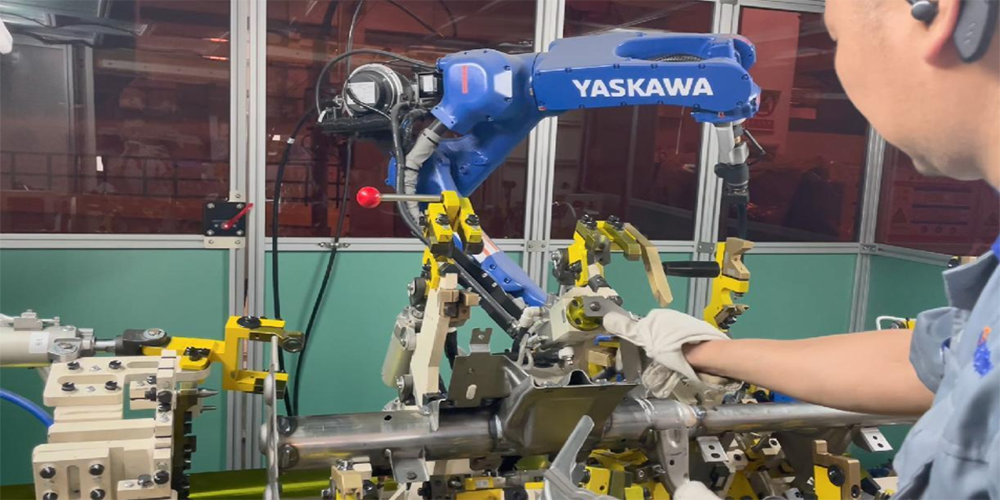

Cov txheej txheem sib dhos zaum kawg feem ntau yog siv cov neeg hlau rau kev sib dhos tsis siv neeg, thiab ntau cov khoom siv hluav taws xob xws li diodes, triodes, amplified tam sim no, rectifier txuas hniav, thiab cov khoom siv hluav taws xob hloov pauv tau siv nyob rau hauv circuits tsav cov neeg hlau.Lub superposition ntawm ib tug loj tus naj npawb ntawm harmonics yuav tsis tsuas cuam tshuam rau lub hwj chim mov system, tab sis kuj yuav ua rau tuag taus lub neej thiab kev ua hauj lwm precision ntawm tus neeg hlau.

Post lub sij hawm: May-17-2023

.png)

.png)