TTM Group yog lub tuam txhab muaj peev xwm tsim cov khoom siv hluav taws xob automation vuam khoom.Peb cov khoom tau siv dav hauv kev tsim tsheb, thiab muaj kev ntseeg siab thiab qhuas los ntawm cov neeg siv khoom.Peb cov khoom siv hluav taws xob automation vuam khoom feem ntau suav nrog cov tshuab vuam tshuab, cov khoom siv laser vuam, cov khoom siv roj shielded vuam, thiab lwm yam. Cov khoom no yog tsim thiab tsim los ntawm peb cov kws tshaj lij, muaj kev ua haujlwm siab, ruaj khov thiab kev nyab xeeb.

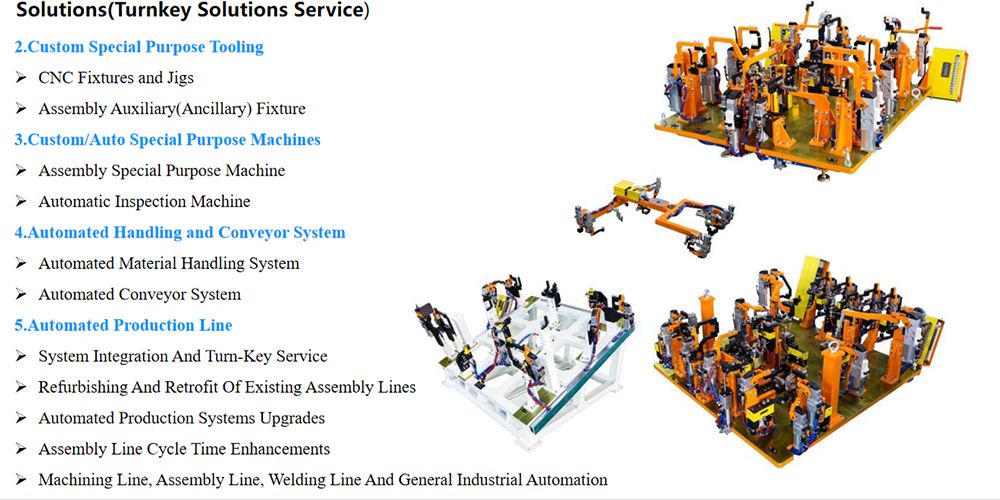

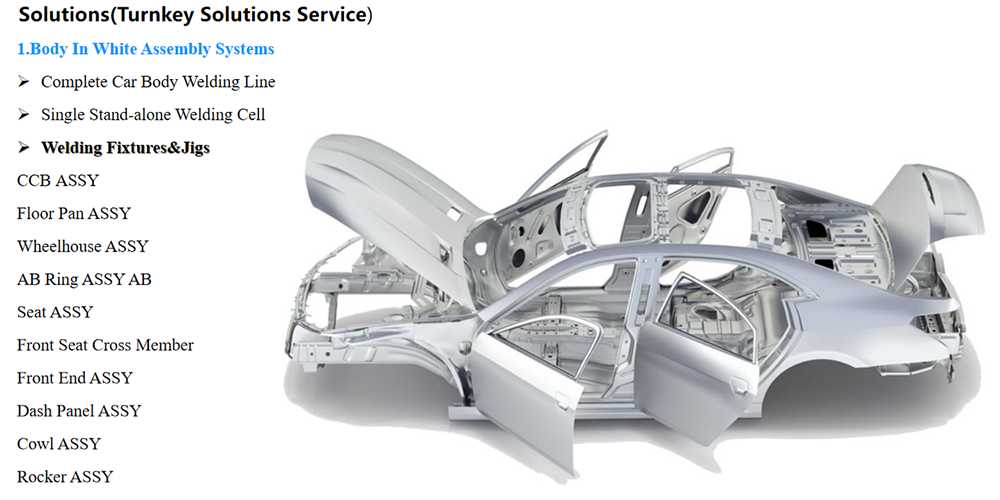

Txij li cov qauv ntawm lub tsheb yog qhov nyuaj tshaj li cov khoom siv tshuab zoo tib yam, kev sib dhos thiab vuam txheej txheem yog qhov nyuaj, thiab cov ntim ntau lawm yog qhov loj, tshwj xeeb tshaj yog lub tsheb tsim lub cev ib txwm ua kev lag luam nrog cov kev siv high-tech.Tus yuam sij yog tsuas yog los ntawm loj-scale vuam robots thiab lub tshuab xam zauv.Lub cev vuam ntau lawm kab tsim los ntawm cov khoom siv thee tsis siv neeg siab heev.

Feem ntau ntawm lub tsheb lub cev yog tsim los ntawm cov khoom siv hlau thiab npog qhov chaw, thiab ntau yam khoom siv ua ntej, xws li cov ncej cua, qhov rooj ncej, qhov rooj sab sauv, sab pem hauv ntej thiab nram qab fenders, pem hauv ntej thiab nram qab panels, sab saum toj npog, thiab lwm yam. yog sib sau ua ke los ntawm vuam thiab riveting, uas welding yog ib qho tseem ceeb kauj ruam nyob rau hauv lub tsheb sib dhos kab.

Nyob rau hauv xyoo tas los no, cov tuam txhab tsheb loj hauv tsev tau pib siv cov vuam neeg hlau lub cev vuam kab, thiab ob peb ntawm lawv tau ua kom pom lub ntiaj teb ua lub zog ua haujlwm.Ntawm cov neeg hlau no, qhov chaw vuam robots suav nrog feem ntau.

Nyob rau hauv xyoo tas los no, lub laser vuam lub cev tshuab tau maj mam hloov qhov chaw vuam tshuab, uas tuaj yeem ua tau raws li qhov xav tau zoo tshaj plaws hauv kev ua haujlwm ntawm qhov chaw pib.Siv cov thev naus laus zis tshiab no, qhov sib koom ua ke ntawm qhov dav ntawm cov khoom sib txuas tuaj yeem raug txo kom tsawg, uas tsis tsuas yog txo qhov kev thov rau daim hlau xwb Nws kuj ua rau lub cev rigidity.Laser vuam qhov chaw, yeej tsis muaj deformation nyob rau hauv vuam qhov chaw ntawm qhov chaw, vuam ceev yog ceev, thiab tsis tas yuav tsum tau tom qab vuam thaum tshav kub kub kev kho mob.Laser vuam muaj peev xwm zoo nyob rau hauv cov nqe lus ntawm kev ua hauj lwm efficiency, kev lag luam, kev ruaj ntseg, lub zog, thiab corrosion kuj.Thiab cov cuab yeej tshiab no kuj tau dhau los ua cov tshuab tseem ceeb thiab cov cuab yeej siv hauv kev tsim khoom lag luam.

Peb cov khoom siv hluav taws xob automation vuam khoom tau siv dav hauv ntau lub tuam txhab tsim tsheb los pab cov neeg siv khoom paub txog kev tsim khoom siv hluav taws xob, txhim kho kev tsim khoom thiab zoo, thiab tsim kom muaj txiaj ntsig ntau dua rau cov neeg siv khoom.Peb yuav txuas ntxiv txhawb kev tsim kho thev naus laus zis thiab cov khoom lag luam tshawb fawb thiab kev tsim kho, muab cov neeg siv khoom zoo dua qub thiab cov kev pabcuam, thiab pab txhim kho kev lag luam tsheb.

Post lub sij hawm: Apr-28-2023

.png)

.png)