automation stamping vuam fixture tsim kev pab cuam chaw tsim tshuaj paus

Video

Specification

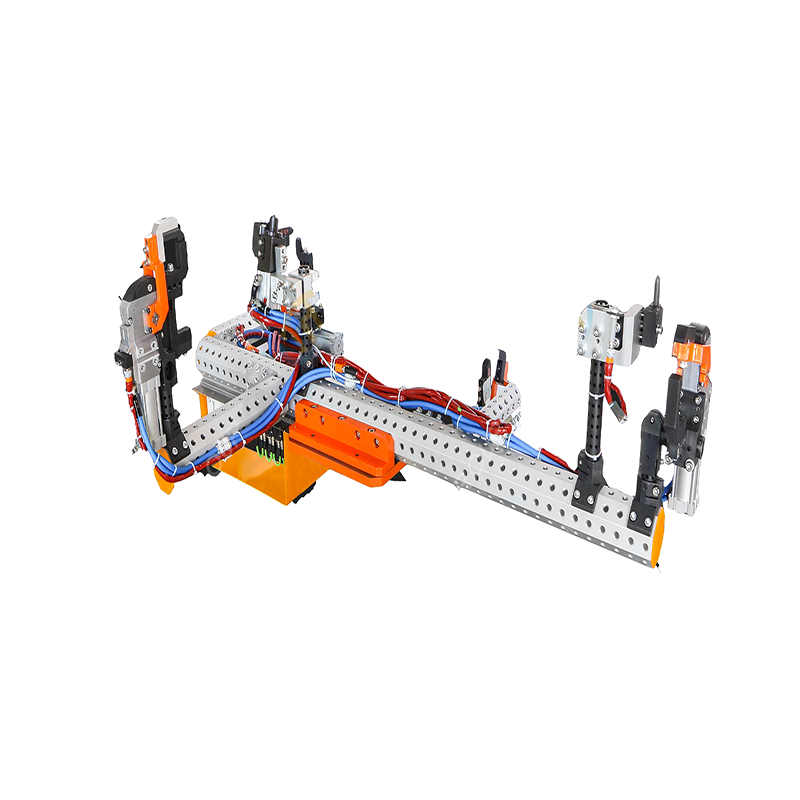

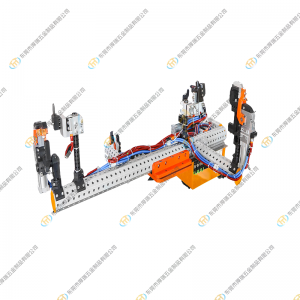

| Vuam hom: | ARC Vuam |

| Vuam Fixtures: | 6 Teeb |

| Gripers: | 4sets |

| Khoom siv: | Hlau |

| Exporting Lub Nroog: | Canada |

Khoom Paub meej

Taw qhia ntxaws

Qhov no yog ib pawg ntawm vuam fixture ntawm AB Nplhaib, tag nrho hauv 15 teeb, peb ua rau peb cov neeg siv khoom Canada.Vuam ntau lawm kab ntau yam, me me batch thiab lub voj voog luv luv yog cov yam ntxwv tseem ceeb ntawm kev lag luam niaj hnub kev lag luam.Cov tsos ntawm no feature txhawb cov creation ntawm lub tswv yim ntawm saj zawg zog fixture thiab kev loj hlob ntawm technology.Raws li lub voj voog ntawm kev rov ua dua tshiab ntawm cov khoom lag luam tau luv dua thiab luv dua, yuav ua li cas hloov pauv ntawm cov qauv qub mus rau cov qauv tshiab thiab ua kom luv luv ntawm lub voj voog yog qhov kev tshawb fawb ntawm txhua lub pov haum.

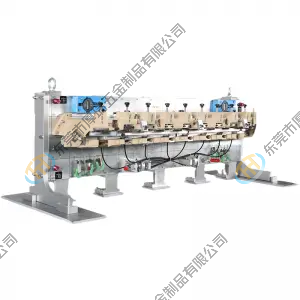

Vuam fixture mas suav nrog fixture hauv qab phaj, clamp tshwj xeeb, auxiliary mechanism, tswj system ntau qhov chaw.Lub phaj hauv qab yog lub chassis ntawm fixture Cheebtsam, tsis siv neeg vuam phom, lifter thiab lwm yam fixture Cheebtsam.Nws yog qhov tseem ceeb ntawm vuam fixture, thiab nws qhov tseeb ncaj qha cuam tshuam qhov tseeb ntawm qhov chaw ntawm lub tshuab.Circular seam tsis siv neeg vuam tshuab yog ib hom universal tsis siv neeg vuam cov cuab yeej uas tuaj yeem ua tiav txhua yam ntawm cov voj voog thiab lub voj voog.Nws tuaj yeem siv rau cov hlau tsis muaj hlau, cov hlau tsis muaj steel, txhuas thiab nws cov hlau thiab lwm yam khoom siv vuam zoo, thiab tuaj yeem xaiv argon arc vuam (xaim lossis tsis xaim), melting electrode gas vuam, plasma vuam thiab lwm yam vuam fais fab. los tsim ib lub nplhaib seam tsis siv neeg vuam system.Nws tuaj yeem siv dav hauv kev vuam ntawm hydraulic lub tog raj kheej, tsheb kev taw qhia ncej, tsav ncej, roj cia lub tog raj kheej, tshuaj thiab kho mob ntim, liquefied roj tso tsheb hlau luam, cov khoom siv hluav taws xob tua hluav taws, chais thiab kua cia lub tog raj kheej. rau mining thiab ntau lawm kab, thiab lwm yam.

Txoj Haujlwm Ua Haujlwm

1. Tau txais daim ntawv xaj khoom------>2. Tsim------>3. Kev lees paub cov duab kos / kev daws teeb meem------>4. Npaj cov ntaub ntawv------>5. CNC------>6. CWM------>6. Kev sib dhos------>7. CMM-> 8. Kev tshuaj xyuas------>9. (kev tshuaj xyuas thib 3 yog xav tau)------>10. (Internal / cov neeg siv khoom ntawm qhov chaw)------>11. Ntim (ntoo lub thawv)------>12. Kev xa khoom

Manufacturing kam rau ua

1. Lub Flatness ntawm Base Phaj 0.05/1000

2. Lub Thickness ntawm Base Phaj ± 0.05mm

3. Qhov Chaw Datum ± 0.02mm

4. Qhov Nto ± 0.1mm

5. Kev Ntsuas Pins thiab Qhov ± 0.05mm

-300x3001.png)

.png)

.png)