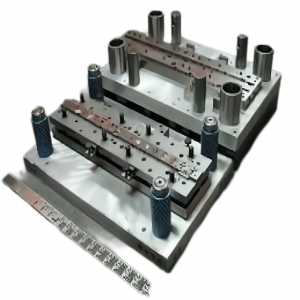

Welding Fixture For Cross Member WS Spring Link

Video

Daim ntawv thov teb

Automotive kev lag luam kev tswj kom zoo

Automotive ntau lawm kab ntau lawm muaj peev xwm txhim kho

Specification

| Hom Fixture: | Arc Vuam |

| Loj: | 1800x1300x900mm |

| Qhov hnyav: | 125 KG |

| Khoom siv: | Main Siv: hlau Kev them nyiaj yug: hlau |

| Kev kho deg: | Plate Plate: Electroplating Chromium thiab Dub Anodized |

Khoom Paub meej

Taw qhia ntxaws

Qhov no yog batch ntawm vuam fixture ntawm WL Cross Member WS Spring Link, tag nrho nyob rau hauv 2 teev, peb ua rau peb cov neeg siv khoom Canada.Lub caij nplooj ntoos hlav chuck shank yog ib lub cylindrical fixture ntsia rau hauv lub tshuab milling rau kaw ib tug laum los yog ib tug milling cutter.Ntxig lub chuck rau hauv lub ntsuas phoo thiab maj mam muab lub xauv lub txiv ntoo nrog lub caij nplooj ntoos hlav chuck rau ntawm lub shank, connector lossis spindle.Nyob ntawm qhov elasticity ntawm elastic steel kom nruj, xoob clamp yooj yim, feem ntau yog siv rau clamping lub teeb, nruab nrab load txiav cov cuab yeej.Nws feem ntau yog siv rau clamping tej cuab yeej xws li kawg mills, laum khoom, kais dej, reamers thiab center xyaum.Hloov cov clamping ntau los ntawm kev hloov cov khoom sib txawv.Thaum clamping, xov ib feem ntawm lub caij nplooj ntoos hlav chuck, xauv txiv ntseej thiab qhov chaw thiab lub khob hliav qab yuav tsum tau ntxuav.Thaum lub sij hawm installation ntawm lub chuck thiab xauv txiv ntseej, lub chuck thiab xauv txiv ntseej yuav tsum tau tilted mus rau ib tug tej lub kaum sab xis thiab ces muab tso rau hauv lub xauv qhov ntawm lub xauv txiv ntseej.Tsis txhob siv lub zog txuas txuas ntxiv ntawm cov ciaj ntswj yog nruj heev, txhawm rau tiv thaiv cov cuab yeej tsis zoo thiab cov khoom siv.

Txoj Haujlwm Ua Haujlwm

1. Tau txais daim ntawv xaj khoom------>2. Tsim------>3. Kev lees paub cov duab kos / kev daws teeb meem------>4. Npaj cov ntaub ntawv------>5. CNC------>6. CWM------>6. Kev sib dhos------>7. CMM-> 8. Kev tshuaj xyuas------>9. (kev tshuaj xyuas thib 3 yog xav tau)------>10. (Internal / cov neeg siv khoom ntawm qhov chaw)------>11. Ntim (ntoo lub thawv)------>12. Kev xa khoom

Manufacturing kam rau ua

1. Lub Flatness ntawm Base Phaj 0.05/1000

2. Lub Thickness ntawm Base Phaj ± 0.05mm

3. Qhov Chaw Datum ± 0.02mm

4. Qhov Nto ± 0.1mm

5. Kev Ntsuas Pins thiab Qhov ± 0.05mm

Txheej txheem

CNC Machining (Milling / Tig), Sib Tsoo

Electroplating Chromium thiab Dub Anodized kho

Lub Sij Hawm Tsim (h): 40h

Lub Sijhawm Ua Haujlwm (h): 150h

Kev Tswj Xyuas Zoo

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Peb tog Certification ua los ntawm ShenZhen Silver Basis Testing Technology Co., Ltd, ISO17025 Certified

.png)

.png)