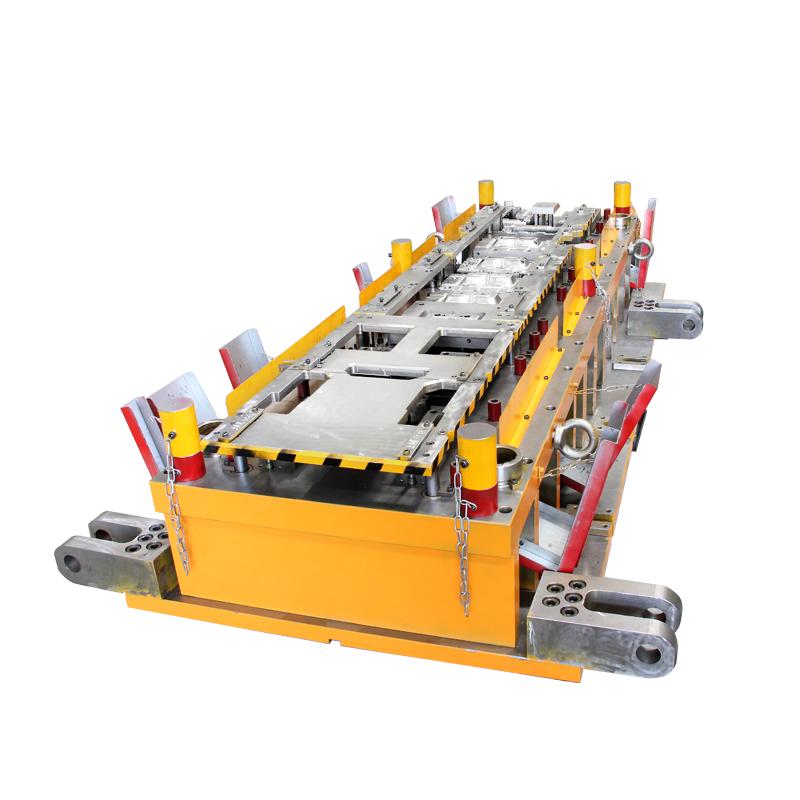

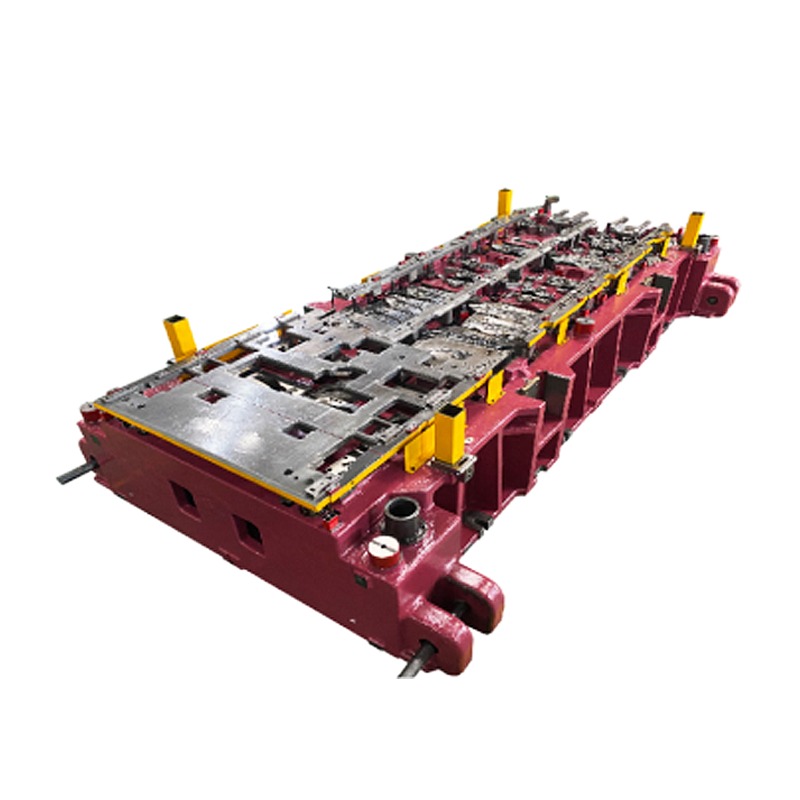

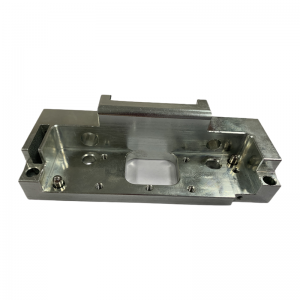

OEM kev cai siab precision progressive punching sib sib zog nqus daim duab pwm casting thiab ntawv hlau pwm stamping tuag tooling

Video

Muaj nuj nqi

Progressive tuag, tseem hu ua kev tuag tas mus li, qhov tuag muaj ob lossis ntau tshaj ob qhov chaw nres tsheb, tuaj yeem ua tiav ob lossis ntau tshaj ob txoj haujlwm stamping hauv ntau qhov chaw.

Daim ntawv thov teb

Automotive kev lag luam rau qhov chaw ntawm lub tsheb.

Automotive ntau lawm kab ntau lawm muaj peev xwm txhim kho.

Khoom Paub meej

Taw qhia ntxaws

Cov kev cai tseem ceeb ntawm kev tsim qauv tuag yog: kev tsim cov tuag yuav tsum xyuas kom meej tias cov khoom tawm ntawm cov duab kos raws li cov duab thiab qhov loj me, cov qauv tuag yog qhov yooj yim, ruaj khov, yooj yim txij nkawm, ruaj khov;Yooj yim rau kev khiav lag luam, kev nyab xeeb thiab txhim khu kev qha ua haujlwm;Yooj yim los tsim, tus nqi qis.

Cov kauj ruam dav dav ntawm kev tsim tuag

Ua ntej, sau cov ntaub ntawv tsim nyog, kev tshuaj xyuas ntawm cov txheej txheem stamping.Xws li: yuav tsum muaj kev pom tiav, cov kev xav tau meej kos duab lossis cov qauv, rau cov duab ntawm qhov chaw, qhov loj me, qhov xav tau precision thiab kev sib koom ua ke muaj kev nkag siab zoo;Nkag siab txog daim npav txheej txheem stamping (feem ntau yog muab los ntawm tus kws tshaj lij stamping), txhawm rau kawm nws ua ntej thiab tom qab.Kev sib raug zoo ntawm cov txheej txheem thiab cov txheej txheem ua tiav yuav tsum muaj kev lav phib xaub ntawm cov txheej txheem, thiab tus naj npawb thiab hom tuag yuav tsum raug txiav txim siab raws li cov txheej txheem txheej txheem teev tseg hauv daim npav txheej txheem;Master qhov tsim ntawm qhov chaw (kev sim ntau lawm lossis batch lossis ntau lawm) los txiav txim siab cov qauv pwm, yog siv cov pwm yooj yim lossis ntau txoj haujlwm siab pwm pwm;Nkag siab qhov xwm txheej, qhov loj me thiab cov txheej txheem ntawm cov khoom siv, xws li cov ntaub ntawv lossis cov khoom siv sawb, cov khoom yob lossis cov khoom seem;Nkag siab txog cov xovxwm thiab lwm yam kev qhia tshwj xeeb, txiav txim siab txog kev tshem tawm thiab lwm yam kev pabcuam ntawm cov pwm raws li cov khoom xaiv:

Nkag siab txog kev quab yuam, cov khoom siv thiab kev ua haujlwm ntawm kev tsim pwm, los muab lub hauv paus rau kev txiav txim siab cov qauv ntawm pwm.Raws li kev tshawb fawb thiab kev nkag siab ntawm cov ntaub ntawv no, yog tias nws pom tias cov txheej txheem stamping tsis zoo, nws yuav tsum yog nyob rau hauv cov ntaub ntawv tsis cuam tshuam rau nws cov kev ua tau zoo, muab tso rau pem hauv ntej kom yooj yim rau kev hloov kho, kom cov khoom tsim, stamping. txheej txheem kev npaj, pwm tsim thiab pwm tsim ntawm kev sib xyaw ua ke zoo dua, kom ua tiav cov txiaj ntsig zoo dua.

Thib ob, txiav txim siab txog cov txheej txheem kev lag luam thiab kev lag luam yog cov txheej txheem txheej txheem stamping tsim nyog.Raws li cov duab ntawm cov khoom, qhov tseeb qhov tseeb, qhov kev xav tau ntawm cov txheej txheem kev soj ntsuam, txiav txim siab qhov xwm txheej ntawm cov txheej txheem yooj yim, xws li blanking, xuas nrig ntaus, khoov thiab lwm yam txheej txheem yooj yim (qhov txheej txheem yooj yim no, feem ntau tuaj yeem ncaj qha los ntawm qhov yuav tsum tau ua. ntawm daim ntawv qhia los txiav txim>; Raws li cov txheej txheem suav los txiav txim seb tus lej ntawm cov txheej txheem, xws li lub sijhawm kos duab, thiab lwm yam . tom qab khoov lossis khoov tom qab xuas nrig ntaus; Raws li cov khoom tsim tawm thiab cov xwm txheej los txiav txim siab cov txheej txheem sib xyaw, xws li cov txheej txheem stamping, cov txheej txheem nruam stamping, thiab lwm yam.

Thib peb, kev xaiv ntawm daim ntawv pwm.Thaum qhov xwm txheej ntawm cov txheej txheem, qhov sib lawv liag thiab kev sib xyaw ua ke ntawm cov txheej txheem tau txiav txim siab, uas yog, txhawm rau txiav txim siab cov txheej txheem stamping, lub sijhawm no yuav tsum tau txiav txim siab cov txheej txheem ntawm cov qauv pwm (pwm daim ntawv xaiv saib cov lus piav qhia hauv qab no) .

Plaub, cov txheej txheem tsim nyog suav.Feem ntau suav nrog: suav ntawm qhov loj me me, txhawm rau npaj cov qauv raws li kev lag luam feem ntau thiab kev txiav txim siab tsim nyog ntawm kev siv cov khoom siv;Xam cov punching siab (xws li xuas nrig ntaus, dabtsi yog khoov quab yuam, tensile quab yuam, unloading quab yuam, thawb quab yuam, blank tuav quab yuam, thiab lwm yam) thiaj li yuav txiav txim siab xovxwm;Xam qhov chaw siab ntawm qhov tuag, thiaj li tsis cuam tshuam qhov zoo ntawm qhov tuag los ntawm eccentric load;Xam lossis kwv yees qhov tseem ceeb ntawm cov pwm (concave tuag, punch tsau phaj, ncoo, punch, thiab lwm yam) qhov ntev, nrog rau qhov siab dawb ntawm cov roj hmab los yog lub caij nplooj ntoos hlav;Txiav txim siab qhov clearance ntawm convex thiab concave tuag, xam qhov loj ntawm convex thiab concave tuag ua hauj lwm ib feem;Txiav txim siab seb qhov khoob khoob khoob yog siv rau qhov kos duab tuag, tus naj npawb ntawm daim duab thiab qhov nruab nrab.Txheej txheem pwm loj faib thiab ib nrab tiav cov khoom loj xam.

Thib tsib, tag nrho cov qauv tsim ntawm pwm.Raws li kev txheeb xyuas thiab kev suav saum toj no, tag nrho cov pwm tsim tuaj yeem ua tiav.Feem ntau, cov qauv yog sketch ua ntej, thiab kaw qhov siab ntawm pwm yog xam ua ntej, thiab cov duab loj ntawm pwm yog txiav txim siab.Nyob rau lub sijhawm no, cov qauv ntawm txhua yam tuaj yeem tsim los txiav txim siab txog cov txheej txheem ntxhib.Nws yuav tsum tau muab sau tseg tias cov kauj ruam no yog sib txuas, kev sib koom ua ke thiab ua tiav rau ib leeg los txiav txim siab qhov kev daws teeb meem zoo tshaj plaws.Feem ntau, kev tsim tag nrho yog ua tiav thaum xav txog kev tsim cov qauv ntawm cov khoom siv.Cov kab ke tsis yog kiag li.Cov qauv tsim qauv feem ntau suav nrog cov ntsiab lus hauv qab no:

① Cov khoom ua haujlwm.Xws li cov punch, concave tuag thiab convex thiab concave tuag thiab lwm yam qauv qauv yog ib qho, ua ke los yog inlaid, thiab kev txiav txim siab ruaj khov.

② Nrhiav qhov chaw.Xws li kev siv ntawm qhov chaw phaj, baffle tus pin (tso lossis txav tau), thiab lwm yam, nws daim ntawv muaj ntau, tuaj yeem xaiv lossis tsim raws li qhov xwm txheej tshwj xeeb.Rau kev vam meej tuag, kuj xav txog seb puas yuav siv tus pin baffle thawj zaug, coj tus pin thiab nrug punch (sab ntug).

③ Unloading thiab thawb ntaus ntawv.Unloading feem ntau yog siv ob hom: nruj thiab hloov tau.Cov khoom lag luam tawv nruj feem ntau siv cov qauv qauv ntawm cov ntawv ntim khoom ruaj ruaj, thiab cov khoom siv thauj khoom yooj yim feem ntau siv cov tawv nqaij los yog lub caij nplooj ntoos hlav raws li cov khoom elastic (nws lub caij nplooj ntoos hlav lossis roj hmab yuav tsum tau tsim thiab suav).

④ Qhia qhov chaw.Xws li seb yuav tsum muaj daim ntawv qhia twg thiab yuav siv daim ntawv qhia twg.Yog siv phau ntawv qhia · phau ntawv qhia, txoj kab uas hla thiab qhov ntev ntawm daim ntawv qhia yuav tsum tau txiav txim.

⑤ Kev xaiv ntawm cov pwm thav duab, thiab nws cov installation thiab fixation.

Rau, xaiv cov xovxwm.Kev xaiv cov xovxwm yog ib feem tseem ceeb ntawm kev tsim tuag, thiab hom thiab cov ntsiab lus ntawm cov xovxwm yuav tsum tau txiav txim siab thaum tsim kev tuag.Kev txiav txim siab ntawm hom xovxwm feem ntau yog nyob ntawm qhov yuav tsum tau ua ntawm cov txheej txheem stamping thiab cov qauv ntawm kev tuag.

Txoj Haujlwm Ua Haujlwm

1. Tau txais daim ntawv xaj khoom------>2. Tsim------>3. Kev lees paub cov duab kos / kev daws teeb meem------>4. Npaj cov ntaub ntawv------>5. CNC------>6. CWM------>6. Kev sib dhos------>7. CMM-> 8. Kev tshuaj xyuas------>9. (kev tshuaj xyuas thib 3 yog xav tau)------>10. (Internal / cov neeg siv khoom ntawm qhov chaw)------>11. Ntim (ntoo lub thawv)------>12. Kev xa khoom

Lub sij hawm xa tuaj & Packing

45 hnub tom qab 3D tsim pom zoo

5 hnub ntawm kev nthuav qhia: FedEx los ntawm Cua

Standard Export Ntoo Case

.png)

.png)