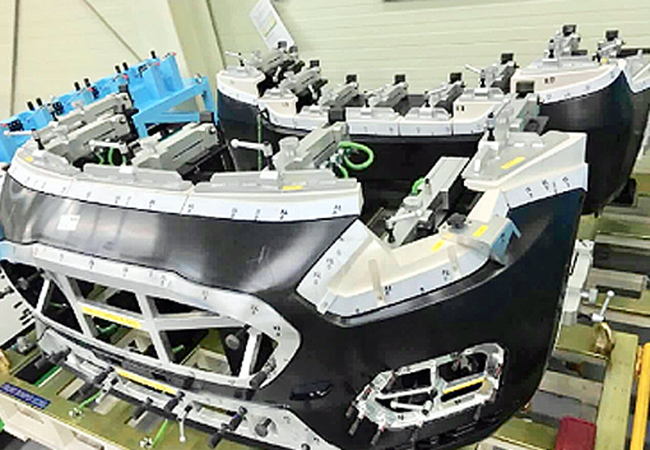

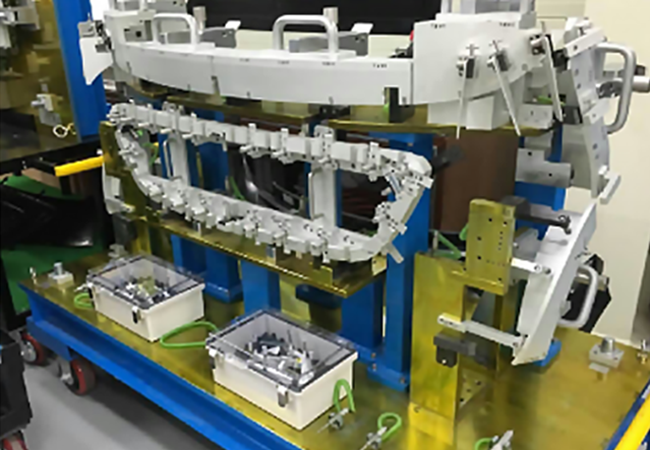

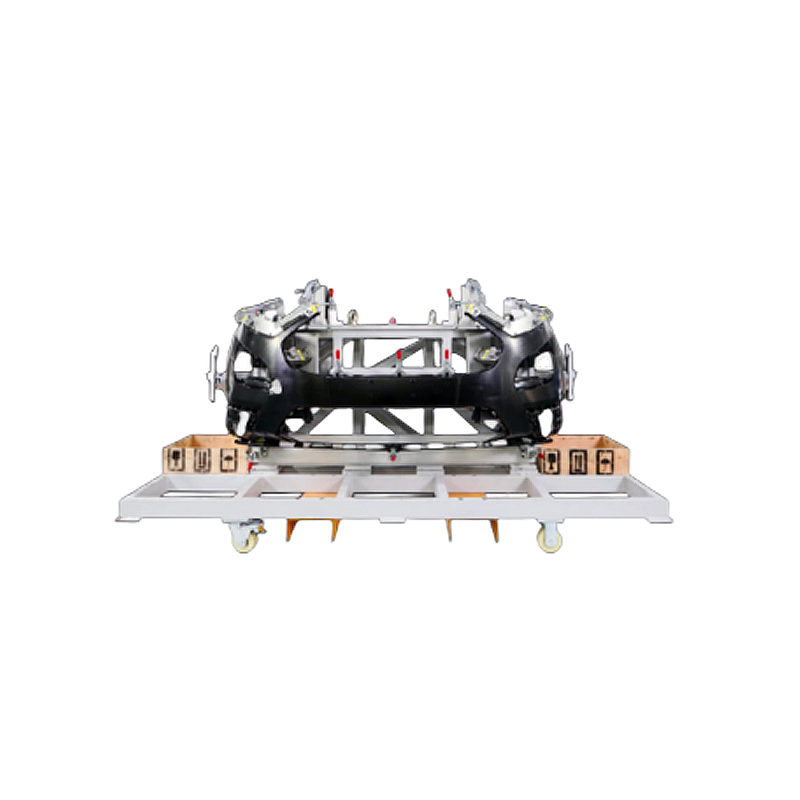

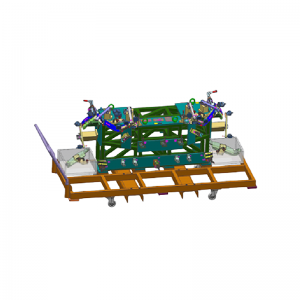

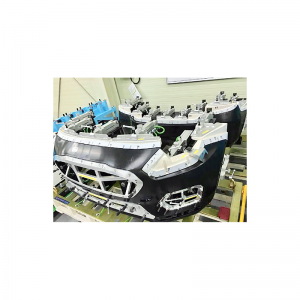

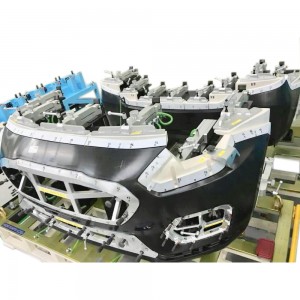

Pem hauv ntej Bumper ASSY Kuaj Fixture

Video

Muaj nuj nqi

Xyuas fixture rau pem hauv ntej bumper los ua ke.Qhov no yog lub tsheb qhov chaw pem hauv ntej bumper sib dhos soj ntsuam cov cuab yeej, los hloov cov kev ntsuas cov cuab yeej, xws li du plug gauge, ntsia hlau plug gauge, sab nraum txoj kab uas hla caliper gauge thiab thiaj li nyob rau mus ntes lub pem hauv ntej bumper los ua ke, txiav txim seb cov khoom puas tsim nyog.

Daim ntawv thov teb

Automotive kev lag luam zoo tswj.

Automotive ntau lawm kab ntau lawm muaj peev xwm txhim kho.

Specification

| Hom Fixture: | Sib dhos Yas Qhov Chaw Tshawb Xyuas Fixtures |

| Loj: | 1450 * 980 * 1180 hli |

| Qhov hnyav: | 145 KG |

Khoom Paub meej

Taw qhia ntxaws

Qhov no yog lub pem hauv ntej bumper ASSY xyuas fixture, uas muaj xws li: lub rooj nyob rau ntawm ob sab ntawm lub workbench, thiab los ntawm cov thawj brackets txhawb dowel tus pin, positioning tus pin rau hnav ib tug scaffold nyob rau hauv lub bar ua ntej los ua ke: teem lub bar ua ntej tus thawj brackets. thiab kev tiv thaiv nyob rau hauv lub bracket los ua ke ua ntej ib tug tej dav hlau thiab qhov thib ob qhov chaw ntawm qhov chaw: lub thib ob brackets, thib ob brackets muaj inconsistent thib peb qhov chaw ntawm stents nyob rau hauv lub bar ua ntej los ua ke: lub thib peb lub rooj zaum: thiab lub zog tig los ua ke teem rau saum kawg. ntawm cov kev txhawb nqa los ua ke nyob rau hauv pem hauv ntej bar ntawm lub worktable: nyob rau hauv lub thib peb lub rooj txhawb nqa, qhov thib ob qhov chaw thiab qhov chaw thib peb qhov chaw yog txav tau nruab nrog tus pin xeem uas tuaj yeem dhau los ntawm lub qhov mounting ntawm lub rooj sib dhos hauv pem hauv ntej. .Cov qauv siv hluav taws xob siv cov pins muab tso rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau nws nws nyob rau hauv pem hauv ntej bar sib raug rau, yog li kom tsis txhob muaj teeb meem ntawm tedious nrhiav kom tau thiab ua yuam kev nyob rau hauv lub dhau los.Cov qauv hluav taws xob muaj feem xyuam rau lub tsheb pem hauv ntej bumper los ua ke soj ntsuam cov cuab yeej, uas muaj xws li ib tug soj ntsuam lub hauv paus, uas ib tug nto nrhiav kom tau thaiv thiab ib tug Qhov ntsuas qhov thaiv yog symmetrically teem.Nws muaj cov yam ntxwv nram qab no: lub hauv paus ntawm fixture tom qab tso lub workpiece qhov bore log nyob rau hauv lub qhov ntawm lub workpiece, lub workpiece txwv tsis pub, nyob rau hauv lub ntsej muag nrhiav kom tau thaiv ntawm ob kawg ntawm lub workpiece, thiab khaws ib tug tej yam sib txawv nrog lub ntsej muag nrhiav pom. thaiv, siv cov cuab yeej ntsuas kev tshuaj xyuas qhov chaw xaus nrog lub workpiece hauv qab dav hlau qhov sib txawv ntawm cov neeg pluag thiab los ntawm lub qhov nrhiav pom thaiv cov khoom cuav ntawm qhov chaw ntawm lub qhov mounting.Cov qauv siv hluav taws xob muaj qhov zoo ntawm cov qauv yooj yim, tsis yog tsuas yog ua kom nws cov kev txhawb nqa txhim khu kev qha thiab ruaj khov, yooj yim nrawm thiab raug tshawb pom, tab sis kuj tseem ua kom yooj yim rau nws cov qauv, thiab yog li txhim kho kev tsim khoom ntawm cov neeg ua haujlwm zoo heev.

Txoj Haujlwm Ua Haujlwm

1. Tau txais daim ntawv xaj khoom------>2. Tsim------>3. Kev lees paub cov duab kos / kev daws teeb meem------>4. Npaj cov ntaub ntawv------>5. CNC------>6. CWM------>6. Kev sib dhos------>7. CMM-> 8. Kev tshuaj xyuas------>9. (kev tshuaj xyuas thib 3 yog xav tau)------>10. (Internal / cov neeg siv khoom ntawm qhov chaw)------>11. Ntim (ntoo lub thawv)------>12. Kev xa khoom

Kev Pabcuam Tomqab Muag

A. Muab cov ntaub ntawv qhia txog kev cob qhia thiab kev cob qhia

B. Muab cov npe khoom seem

C. Pom zoo Spare & Hloov Qhov Chaw

D. Kev ntseeg tau thiab kev ruaj ntseg

E. Cov Khoom Siv Nruab Nrab ntawm Cov Neeg Siv Khoom

F. Kev Pabcuam Hauv Tsev / Kev Txhawb Nqa

G. Tej thaj chaw deb kev pab txhawb rau Commission/Kev daws teeb meem ntawm cov neeg siv khoom Site

Txheej txheem

CNC Machining (Milling / Tig), Sib Tsoo

Electroplating Chromium thiab Dub Anodized kho

Lub Sij Hawm Tsim (h): 40h

Lub Sijhawm Ua Haujlwm (h): 150h

Kev Tswj Xyuas Zoo

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Peb tog Certification ua los ntawm ShenZhen Silver Basis Testing Technology Co., Ltd, ISO17025 Certified

.png)

.png)